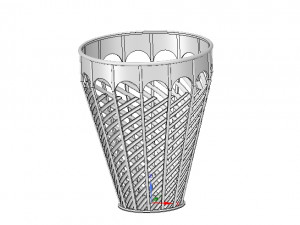

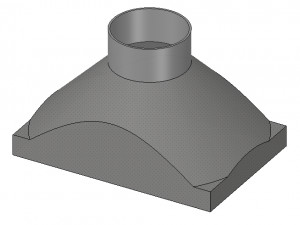

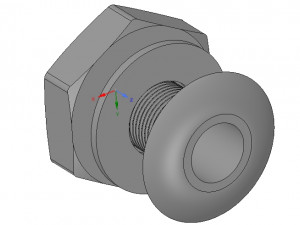

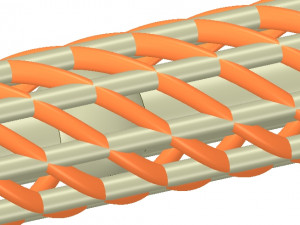

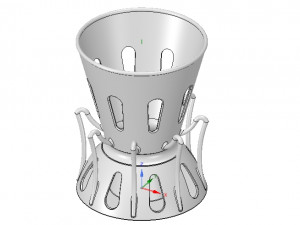

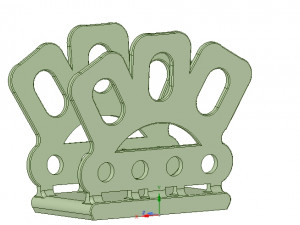

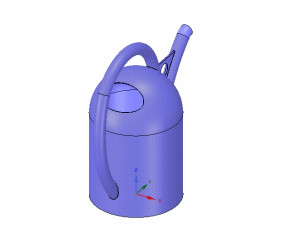

- -50%obj stlDzustoAccessories

- -50%stl stl objDzustoAccessories

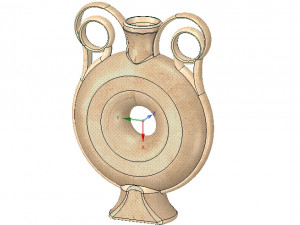

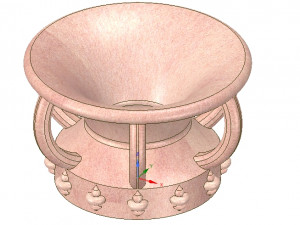

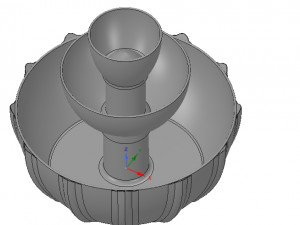

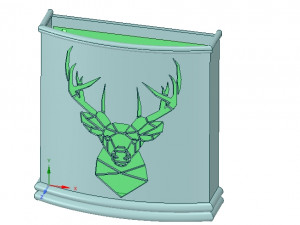

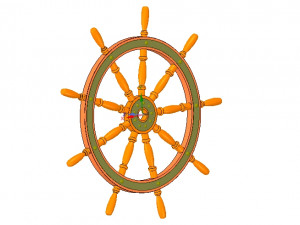

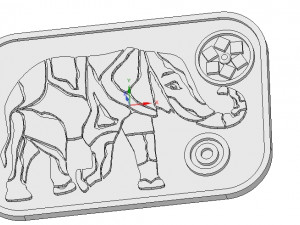

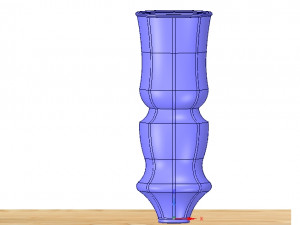

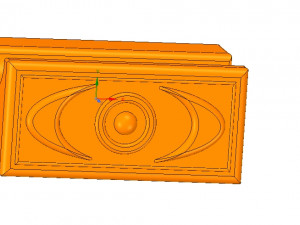

- -50%stl objDzustoDecor

- -50%obj stlDzustoDecor

- -50%obj stlDzustoDecor

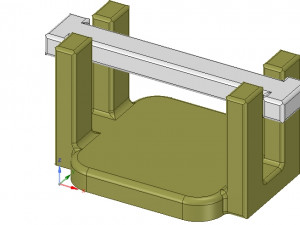

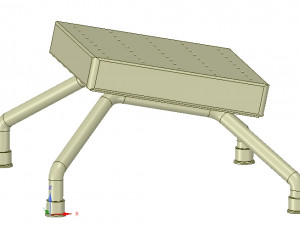

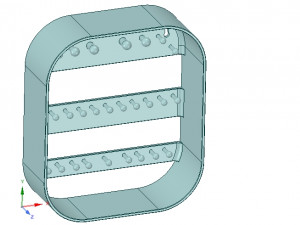

- -50%stl objDzustoFurniture

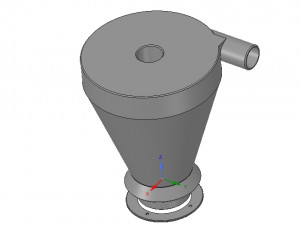

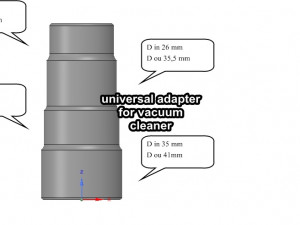

- -50%obj stl obj stlDzustoAccessories

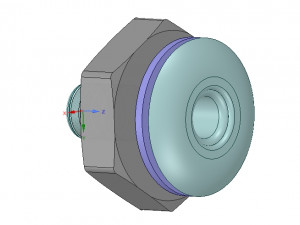

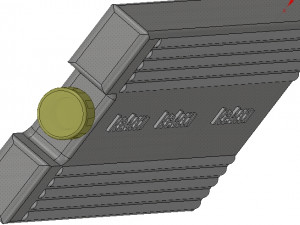

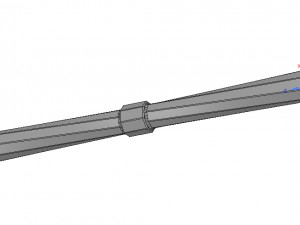

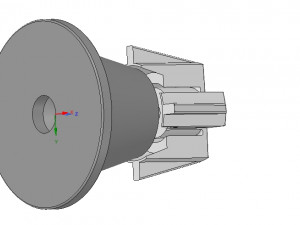

- -50%stl objDzustoHand Tools

- -50%obj stl obj stlDzustoHand Tools

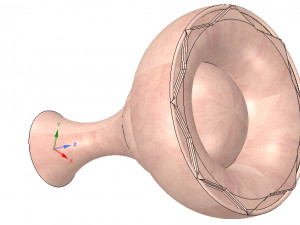

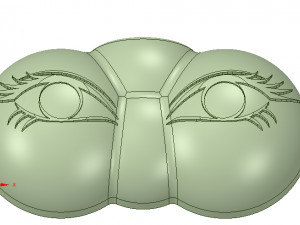

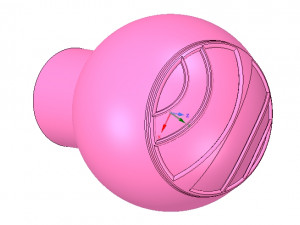

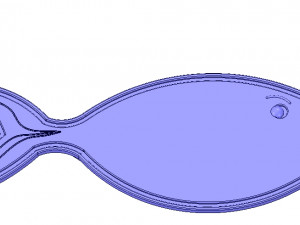

- -50%stl objDzustoSculpture

- -50%obj stl obj stl obj stlDzustoOther

- -50%stl obj stl obj stl objDzustoOther

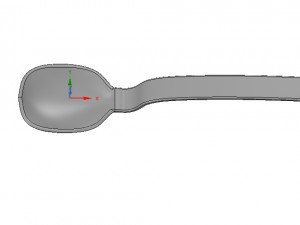

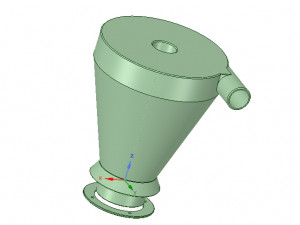

- -50%obj stl obj stlDzustoKitchen and Dining

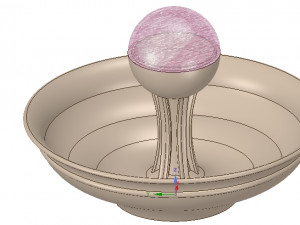

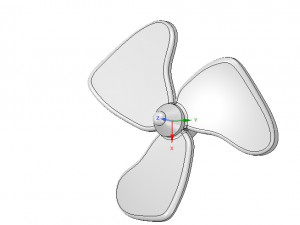

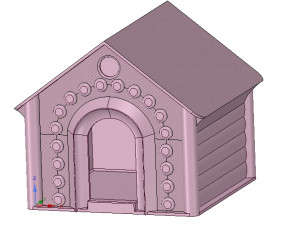

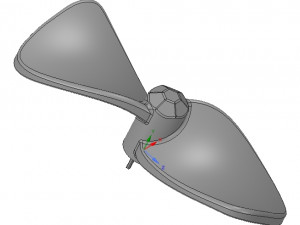

- -50%obj stl obj stl obj stlDzustoOutdoor items

- -50%stl obj obj stlDzustoKitchen and Dining

- -50%stl objDzustoAccessories

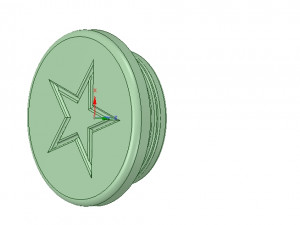

- -50%stl objDzustoCoins and Badges

- -50%stl objDzustoFurniture

- -50%stl objDzustoScans and Replicas

- -50%stl objDzustoAccessories

- -50%stl objDzustoAccessories

- -50%objDzustoFurniture

- -50%obj stl max objDzustoOther

- -50%obj stlDzustoAccessories

- -50%stl objDzustoKitchen and Dining

- -50%obj stlDzustoKitchen and Dining

- -50%obj stlDzustoOutdoor items

- -50%obj stlDzustoDecor

- -50%obj stlDzustoPC and Laptop

- -50%obj stlDzustoFurniture

- -50%obj stlDzustoKitchen and Dining

- -50%obj stlDzustoDecor

- -50%obj stlDzustoOther

- -50%stl obj stl objDzustoOther

- obj stlDzustoCoins and Badges

- -50%obj stlDzustoDecor

- -50%stl obj obj stl obj stlDzustoOther

- -50%obj obj stlDzustoFurniture

- -50%stl max objDzustoHand Tools

- -50%obj obj stl obj stl objDzustoHand Tools

- -50%obj obj stl obj stl obj obj stl objDzustoBathroom

- obj stlDzustoCoins and Badges

Abzeichen:

Beitrittsdatum: 2019-07-15

Letzte Aktivität: 2021-06-04

Modeling products and preparing products for production on CNC machines and 3D printing on production printers. Design of private houses, fences, doors, gates, furniture, industrial and industrial products of a wide range. I will answer all questions, only consider the possible misunderstanding asso.

Engineering design, the creation of electronic forms for the manufacture of prototypes, parts or spare parts for casting aluminum, bronze alloys, resins, plastics and other materials, as well as for cutting, stamping and milling parts on CNC machines taking into account tolerances, fit and conditions processing and grinding of these parts, or printing of parts and products on an industrial 3D printer, including printing with metal mixtures and compositions with different types of application of these compositions on the surface.

The design process follows your drawings, drawings, sketches or full-scale details.

A serious approach to design allows you to avoid problems at the stage of manufacturing parts and manufacturing parts from different materials and on different technological equipment. The use of modern software allows you to significantly speed up the process, creating layouts and prototypes of complex structures with a high level of detail. The resulting product is applicable to paperless production technology. Forms and formats of high-quality models of execution can immediately go to the CAM module for further translation into machine codes for CNC and 3D printers.

The obtained forms can be intended both for casting from a different number of fasteners of the form itself, and for manufacturing one-piece casting or part.

The form or model can be issued, including, in the form of STL AMF model ready to manufacture with a sufficient number of accurate polygons.

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी