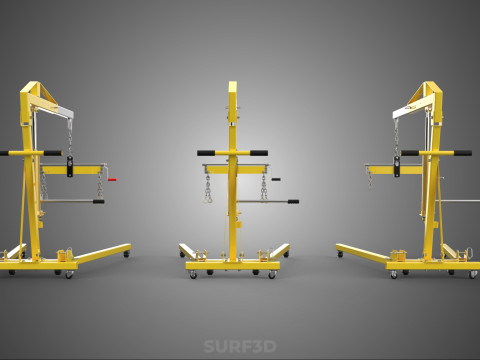

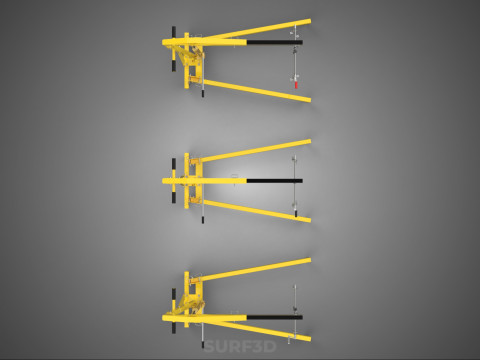

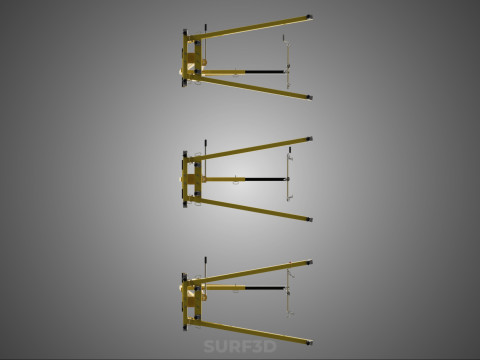

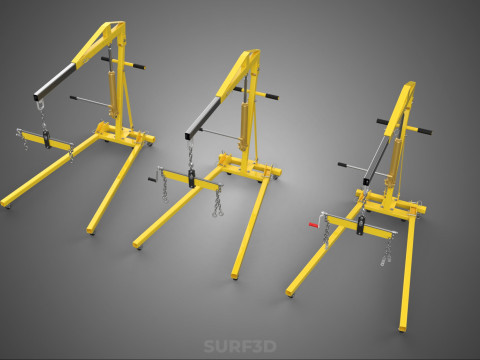

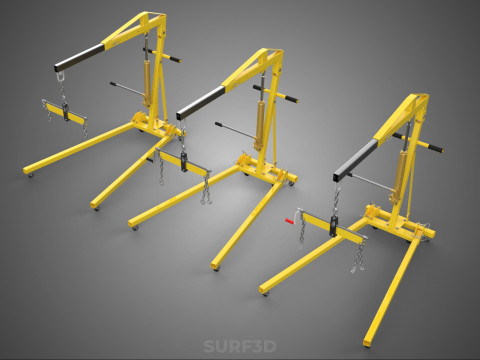

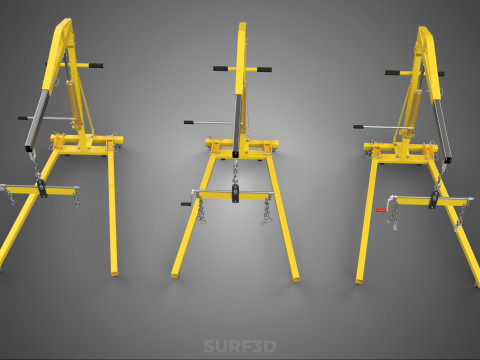

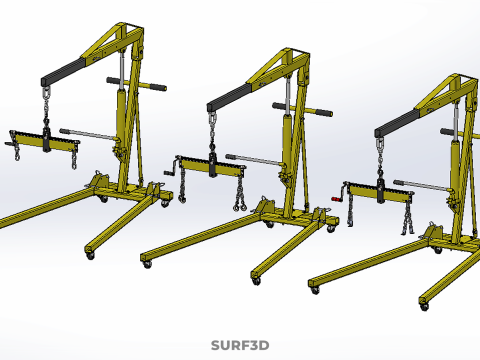

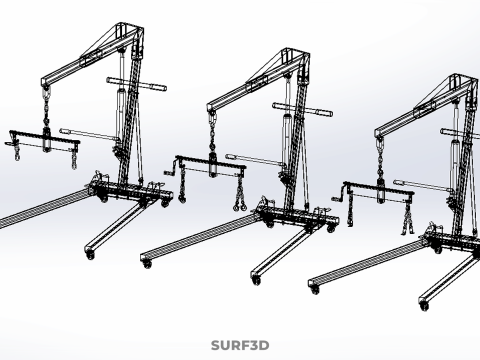

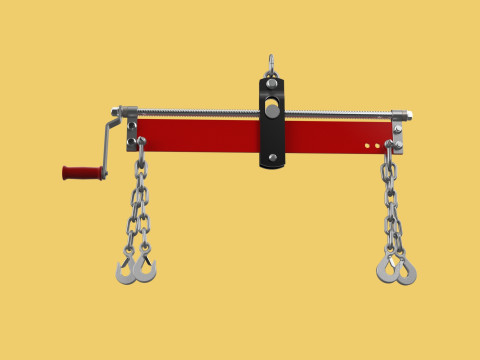

STANDARD CRANE ENGINE HOIST LIFT HYDRAULIC LEVELER BALANCER LOAD 3D-Modell

- Verfügbare Formate: Rhinoceros: 3dm 24.08 MB3DS MAX all ver.: 3ds 8.80 MBBlender: blend 22.41 MBCollada: dae 25.57 MBAutoCAD (native): dwg 21.06 MBAutodesk FBX: fbx 31.63 MBGLB / GLTF: glb 10.75 MBIGES: iges 3.98 MB3DS MAX: max 53.44 MBWavefront OBJ: obj 17.76 MBACIS: sat 23.95 MBSketchUp: skp 8.52 MBSTEP: step 5.09 MBStereolithography: stl 19.77 MB

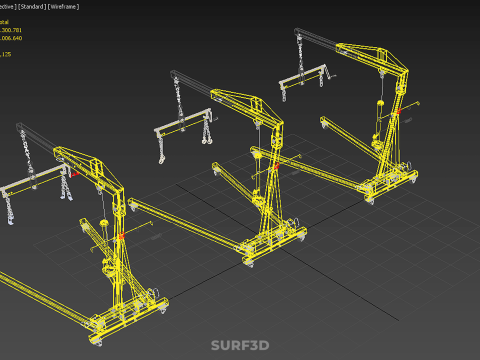

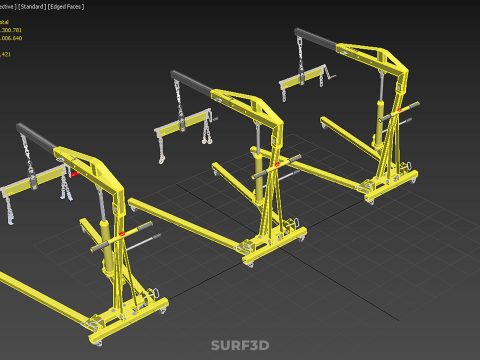

- Polygone:1300781

- Eckpunkte:1006640

- Animiert:No

- Texturen:No

- Rigged:No

- Materialien:

- Low-poly:No

- Sammlung:No

- UVW mapping:No

- Plugins Used:No

- Druckfertige:No

- 3D-Scan:No

- Erwachsene:No

- PBR:No

- KI-Training:No

- Geometrie:Poly NURBS

- Unwrapped UVs:Unknown

- Betrachter:238

- Datum: 2025-06-06

- Artikel-ID:577926

- Bewertung:

High-quality 3D assets at affordable prices — trusted by designers, engineers, and creators worldwide. Made with care to be versatile, accessible, and ready for your pipeline.

Included File Formats

This model is provided in 14 widely supported formats, ensuring maximum compatibility:

• - FBX (.fbx) – Standard format for most 3D software and pipelines

• - OBJ + MTL (.obj, .mtl) – Wavefront format, widely used and compatible

• - STL (.stl) – Exported mesh geometry; may be suitable for 3D printing with adjustments

• - STEP (.step, .stp) – CAD format using NURBS surfaces

• - IGES (.iges, .igs) – Common format for CAD/CAM and engineering workflows (NURBS)

• - SAT (.sat) – ACIS solid model format (NURBS)

• - DAE (.dae) – Collada format for 3D applications and animations

• - glTF (.glb) – Modern, lightweight format for web, AR, and real-time engines

• - 3DS (.3ds) – Legacy format with broad software support

• - 3ds Max (.max) – Provided for 3ds Max users

• - Blender (.blend) – Provided for Blender users

• - SketchUp (.skp) – Compatible with all SketchUp versions

• - AutoCAD (.dwg) – Suitable for technical and architectural workflows

• - Rhino (.3dm) – Provided for Rhino users

Model Info

• - All files are checked and tested for integrity and correct content

• - Geometry uses real-world scale; model resolution varies depending on the product (high or low poly)

• • - Scene setup and mesh structure may vary depending on model complexity

• - Rendered using Luxion KeyShot

• - Affordable price with professional detailing

Buy with confidence. Quality and compatibility guaranteed.

If you have any questions about the file formats, feel free to send us a message — we're happy to assist you!

Sincerely,

SURF3D

Trusted source for professional and affordable 3D models.

More Information About 3D Model :

Here is a detailed, formal, and encyclopedic description for the title "SOME CRANE ENGINES WITH DIFFERENT TYPES OF LOAD BALANCERS":

A crane engine, more accurately described as the prime mover or power unit of a crane system, is the component responsible for generating the mechanical or electrical energy necessary to perform the crane's various operations, including hoisting (lifting and lowering the load), traversing (moving the hoist horizontally along a beam or trolley), slewing (rotating the crane structure horizontally), and sometimes luffing (changing the angle of the boom). The selection and configuration of the engine are heavily influenced by the crane's type, size, power requirements, operational environment, and the characteristics of the loads it is designed to handle.

Crane power units can be broadly categorized into several types:

1. **Electric Motors:** Predominantly used in fixed or rail-mounted cranes such as overhead cranes, gantry cranes, and tower cranes. These utilize electric motors (AC or DC, often controlled by Variable Frequency Drives - VFDs - for precise speed and torque control) drawing power from a grid connection or onboard generator. Electric systems offer high efficiency, low emissions at the point of use, quiet operation, and excellent control capabilities suitable for precision lifting.

2. **Internal Combustion Engines (ICE):** Commonly found in mobile cranes (like crawler cranes, truck-mounted cranes, and rough-terrain cranes) and some larger harbor or port cranes. These typically employ diesel engines to provide power, often driving hydraulic pumps or electrical generators that, in turn, power the various crane functions. ICE-powered systems offer mobility and high power density in locations where grid power is unavailable or impractical.

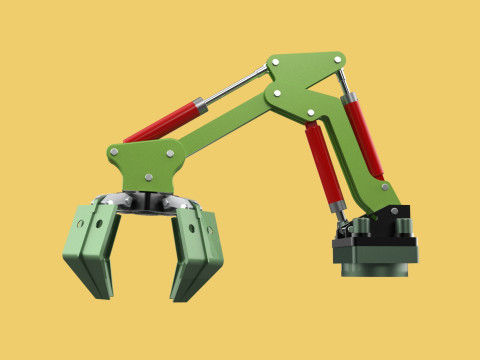

3. **Hydraulic Power Units:** While often powered by electric motors or ICEs, hydraulic systems are a crucial intermediary in many cranes. They convert rotational energy into hydraulic pressure and flow, which then drives hydraulic cylinders or motors responsible for lifting, extending, and articulating crane components. This allows for high force output and smooth control.

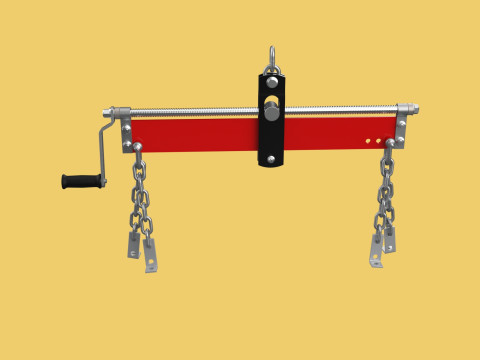

The presence of a significant load introduces substantial forces and moments that challenge a crane's stability, efficiency, and the demands placed upon its power system. "Load balancers," in the context of crane mechanics and operation, refer to systems or components designed to manage these forces, improve stability, reduce energy consumption, or mitigate the dynamic effects of the load. While the term "load balancer" in this specific mechanical context is not always standardized, it generally encomp***** mechanisms that counterbalance the load's effect. Several types of such systems exist:

1. **Counterweights:** This is perhaps the most common type of passive load balancing. Heavy m*****, typically made of steel or concrete, are positioned on the crane structure opposite to the boom and load. The counterweight creates an opposing moment that balances the moment generated by the load and the crane's own structure. This significantly improves the crane's static stability envelope (reducing the risk of tipping) and reduces the torque required from the hoisting engine/motor to lift or hold the load, leading to lower energy consumption and reduced wear on the lifting mechanism. The size and position of counterweights are critical design parameters, often adjustable on larger cranes to suit different load and reach configurations.

2. **Active Stability and Control Systems:** Modern cranes utilize sophisticated electronic control systems that monitor load weight, boom angle, wind speed, and other parameters. These systems can employ hydraulic actuators or variable motor controls to dynamically adjust the crane's configuration or apply counter-forces to maintain stability and dampen load sway. While not strictly "balancing" in the counterweight sense, these systems *manage* the dynamic effects of the load, which impacts the transient loads on the engine and enhances operational safety and efficiency under variable conditions. Anti-sway systems are a prime example, actively controlling trolley or bridge motion to minimize load oscillation during movement, improving precision and reducing dynamic stresses.

3. **Energy Recovery Systems (Regenerative Braking):** Particularly relevant for electric cranes or electric/hydraulic hybrids, these systems capture the potential energy of the load during lowering. Instead of dissipating this energy as heat through friction braking, the hoisting motor acts as a generator, converting the mechanical energy back into electrical energy. This recovered energy can be fed back into the power grid or stored onboard (e.g., in capacitors or batteries). While this system doesn't mechanically counterbalance the static load moment like a counterweight, it *balances* the energy demand profile, significantly reducing net energy consumption during lowering operations and potentially allowing for smaller peak power requirements from the prime mover or power supply infrastructure.

The interplay between crane engines and these load balancing systems is fundamental to safe and efficient operation. Counterweights directly reduce the static torque requirement on the engine/hoist motor. Active systems allow the engine to operate within safer parameters by managing dynamic stresses and improving control. Energy recovery systems optimize the energy usage profile, reducing the overall workload and peak demand on the engine/power source. Therefore, the design and integration of the prime mover with appropriate load balancing technologies are critical engineering considerations for optimizing crane performance, safety, and energy efficiency across various operational scenarios.

KEYWORDS: Crane, Engine, Motor, Power unit, Prime mover, Load, Balancing, Load balancing, Counterweight, Stability, Moment, Hoisting, Lifting, Traversing, Slewing, Electric motor, Internal combustion engine, Diesel engine, Hydraulic power unit, Regenerative braking, Energy recovery, Anti-sway, Dynamic load, Static load, Crane mechanics, Industrial machinery, Heavy lifting, Material handling, Control systems, Variable Frequency Drive (VFD), Crane design.

Druckfertige: NeinFalls Sie ein anderes Format benötigen, eröffnen Sie bitte ein neues Support-Ticket und fragen Sie danach. Wir können 3D-Modelle in folgende Formate konvertieren: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Wir konvertieren keine 3D-Szenen und Formate wie .step, .iges, .stp, .sldprt usw!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी